Some Useful Tips For Paddy Drying To Ensure Better Quality Paddy

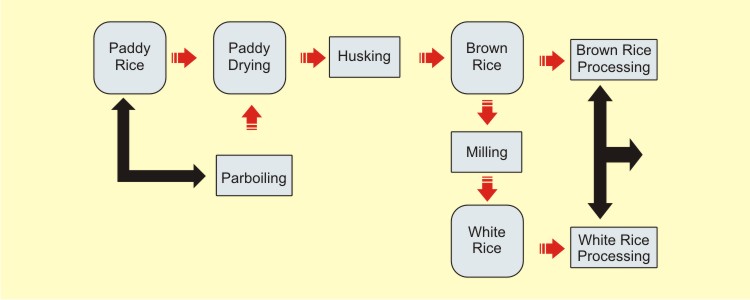

Paddy drying is one of the major ways to ensure better quality paddy and thus rice. Here are some useful tips that can surely increase your chance of having a great paddy drying season in your mill which can lead to an enhancement in your profit figure.

Steps For Proper Paddy Drying

- Paddy, aka rice paddy or rice crop is better to be placed harvested in a drying bin at a depth of around 6 to 12 feet. The amount of depth depends on the initial moisture content of the bulk rice and also capacity of the drying fans.

- Now, level the crop evenly all across the drying bin at the pre-determined depth. Make sure you level the rice uniformly so the air pressure can be distributed in an even way all through the horizontal cross-section of drying bin ensuring unvarying flow of air.

- The subsequent step is to opening the bin exit windows. This would allow exhaust air to exit ready from the crop drying bin.

- The next step is to turning on the fans as soon as all the ducts get covered with around 1 foot or more of the crop.

- Don’t keep wet paddy in the bin, truck, grain cart or combine hopper for more than 12 hours without having the air move through container to let the rice cool.

- Check relative temperature and humidity of ambient air to see the heater’s maximum temperature setting.

- Any reputed paddy dryer plant exercises optimal caution while the temperature of drying air surpasses 1000

- Dry rice with high moisture in shallow batches till the moisture content of the rice is 15 percent or even less. In this situation, you can allow deeper depth with minimized airflow.

- Drying time for each batch is settled by the rate of airflow that is often measured in CFM (cubic feet per minute) per hundredweight, difference in temperature between air entering and exiting rice, moisture content of ambient air and actual moisture content of rice.

- One of the best ways to reduce paddy drying time is increasing airflow. However, this might not be considered to be an energy efficient way of paddy drying.

- As the crop reaches 15 percent moisture, move the content to another bin so as to increase the depth as well as decrease the airflow per hundredweight. You can continue with the drying process until the moisture content (MC) reaches 12.5 percent to 13 percent. Drying rate for low MC crop is slower than the higher MC counterparts.

Crop drying may be done using high pressure fans sans heat. Other paddy dryer uses propane or natural gas for both electricity and heat that are used to power the fans and move heated air through the drying procedure. Both the procedures work well to dry the crops though the effectiveness depends on the weather conditions to a great extent. And both the processes contribute well to energy bill. So both for the farmers and millers, the cost of drying paddy is a big concern.